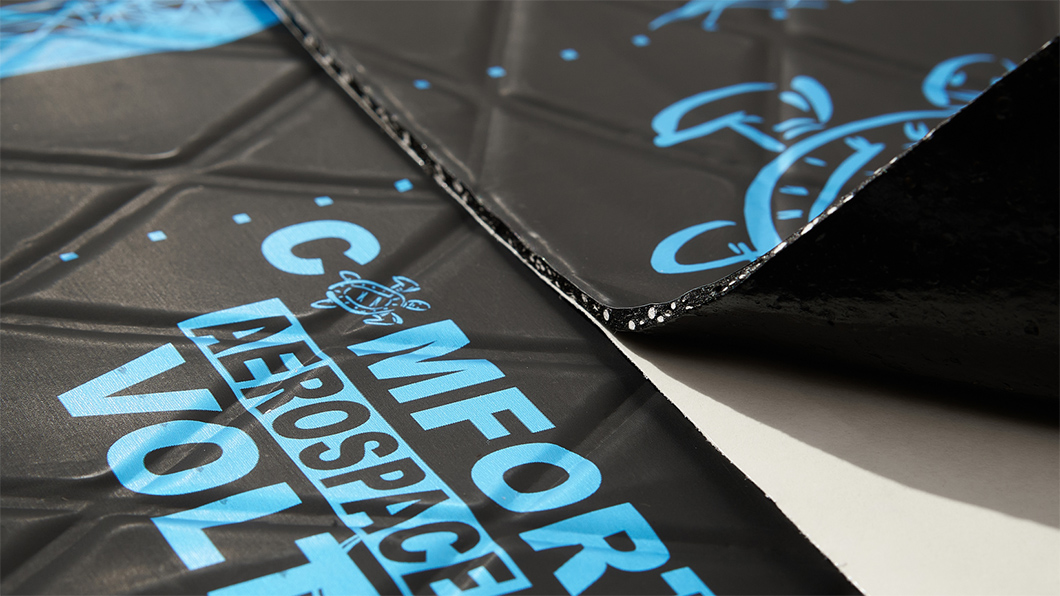

Vibroacoustic material Comfortmat Volt

More about the product

- You can return the goods to us within 14 days

Vibroacoustic Material Comfortmat Volt

Comfortmat Volt is the lightest and thinnest material from the new Aerospace line of vibroacoustic materials, combining effective anti-vibration properties with advanced sound insulation capabilities. This combination makes Volt an exceptionally efficient solution for vehicle soundproofing, where minimizing added weight while achieving real acoustic benefits is desirable – typically in electric and sports cars. With a thickness of only 2.5 mm and an area weight of about 2.2 kg/m², Volt is ideal for application on large and thin body parts prone to resonance – such as roofs, doors, hoods, or trunk lids. In these areas, common thin materials often fail – either due to low efficiency or unnecessary loading of movable or liftable parts. Volt overcomes this contradiction thanks to its unique internal structure and a solid aluminum foil that ensures stability during application and operation. The measured acoustic loss factor (MLF) of 0.36 corresponds to the level of advanced anti-vibration materials, but it is also supplemented by the ability to limit noise penetration – even when applied in a single layer. Volt thus represents a logical choice for professional applications where low weight, high efficiency, and long-term stability are emphasized.

About Comfortmat Aerospace Technology

The Aerospace range materials represent a new generation of vibroacoustic solutions that combine anti-vibration and sound insulation functions in a single step. Unlike traditional damping layers, which often focus only on suppressing vibrations or require multi-stage application, Aerospace uses an advanced sandwich structure capable of effectively absorbing vibrations while significantly reducing sound passage through body panels.

The core of the technology is a vibroacoustic layer with foamed granules – lightweight elastic particles with a bulk density of approximately 0.02 g/cm³, evenly distributed in a polymer matrix with a density of 1.25 g/cm³. The resulting mixture has a final bulk density of 0.58 g/cm³, allowing for high damping levels without a significant weight increase. The combination of two different acoustic environments – a heavy matrix and light, flexible granules – enhances the ability to absorb and dissipate vibrations across a wide frequency spectrum. This structure also contributes to improved sound insulation, even in the area of key low frequencies.

Aerospace technology thus offers an exceptional performance-to-weight ratio, which is a key parameter, especially for electric vehicles, sports cars, and professional soundproofing, where every extra kilo is undesirable. The materials exhibit an acoustic loss factor (MLF) of up to 0.62 (for the Comfortmat Zenith material) in the range of -10 to +40 °C, which is at or above the level of the most effective anti-vibration materials on the market. High adhesive strength in the range of 11 to 16 N/cm (depending on the material type) ensures perfect adhesion even on vertical or curved surfaces without the risk of detachment.

In addition to acoustic parameters, Aerospace materials also have a significant impact on body stiffness. Bending strength tests show that models like Galaxy and Zenith increase the resistance to sheet deformation even more than common anti-vibration materials – thus contributing to the mechanical stability and durability of the entire part. Naturally, there is also low water absorption (below 0.7%) and resistance in a wide temperature range – both in extreme heat and frost.

Main Features

- Combines anti-vibration and sound insulation effects in a single thin layer.

- With a thickness of 2.5 mm and an area weight of 2.26 kg/m², it is ideal for applications focused on low weight.

- The vibroacoustic layer with foamed granule technology in a polymer matrix ensures effective vibration damping and noise reduction.

- The acoustic loss factor (MLF) reaches a value of 0.36, corresponding to the level of advanced anti-vibration materials.

- Significantly reduces resonance of body panels, thus contributing to improved acoustic comfort.

- Contributes to increased sheet stiffness and reduction of resonances in critical frequency bands.

- Features high adhesive strength above 11 N/cm, ensuring reliable application on all surfaces.

- Water absorption below 0.7% ensures long-term resistance to moisture and risk of degradation.

- Resists both long-term and short-term temperature stress (-40 to 90 °C), stable even in extreme conditions.

- Non-flammable composition meets increased safety requirements for application in interiors and engine compartments.

How to Apply

Comfortmat Volt is applied in a single layer directly onto a cleaned and degreased body surface. Due to its high adhesive strength, the use of a pressure roller is not necessary; thorough manual pressing over the entire surface is sufficient. For perfect results, however, rolling is recommended, especially on more complex or vertical surfaces. Given the thickness of 2.5 mm and an acoustic loss factor of 0.36, Volt is suitable primarily for areas with medium levels of vibration and noise load – where it is necessary to reduce resonance without significant weight increase. Typical application areas include:

- hood

- inner door panel

- outer door panel

- roof

- trunk lid

- fenders

About Comfortmat Materials

Comfortmat has been operating in the market since 2010 and has quickly established itself as a leading global manufacturer of anti-vibration and sound insulation materials. Comfortmat has introduced new technologies to the automotive industry, enabling maximum efficiency, lower material weight, consistent performance even in extreme temperatures, and last but not least, very easy application. In recent years, Comfortmat has been setting the direction in vehicle soundproofing and regularly brings to the market materials with record efficiency and excellent properties that were previously unattainable. This is possible only through years of research in Comfortmat laboratories, the highest quality control at every stage of production, modernization of production machines involving leading global experts in automating production lines, and the creation of a research center equipped with the most modern devices. Highly qualified Comfortmat experts have extensive scientific and production experience, regularly conduct essential physical and mechanical tests, and possess expertise in the vibroacoustic properties of cars. Thanks to this, Comfortmat products can meet the most demanding requirements of the current automotive market.| Catalog number | COM VOLT |

| Brand | Comfortmat |

| Oversized shipment | Yes, |